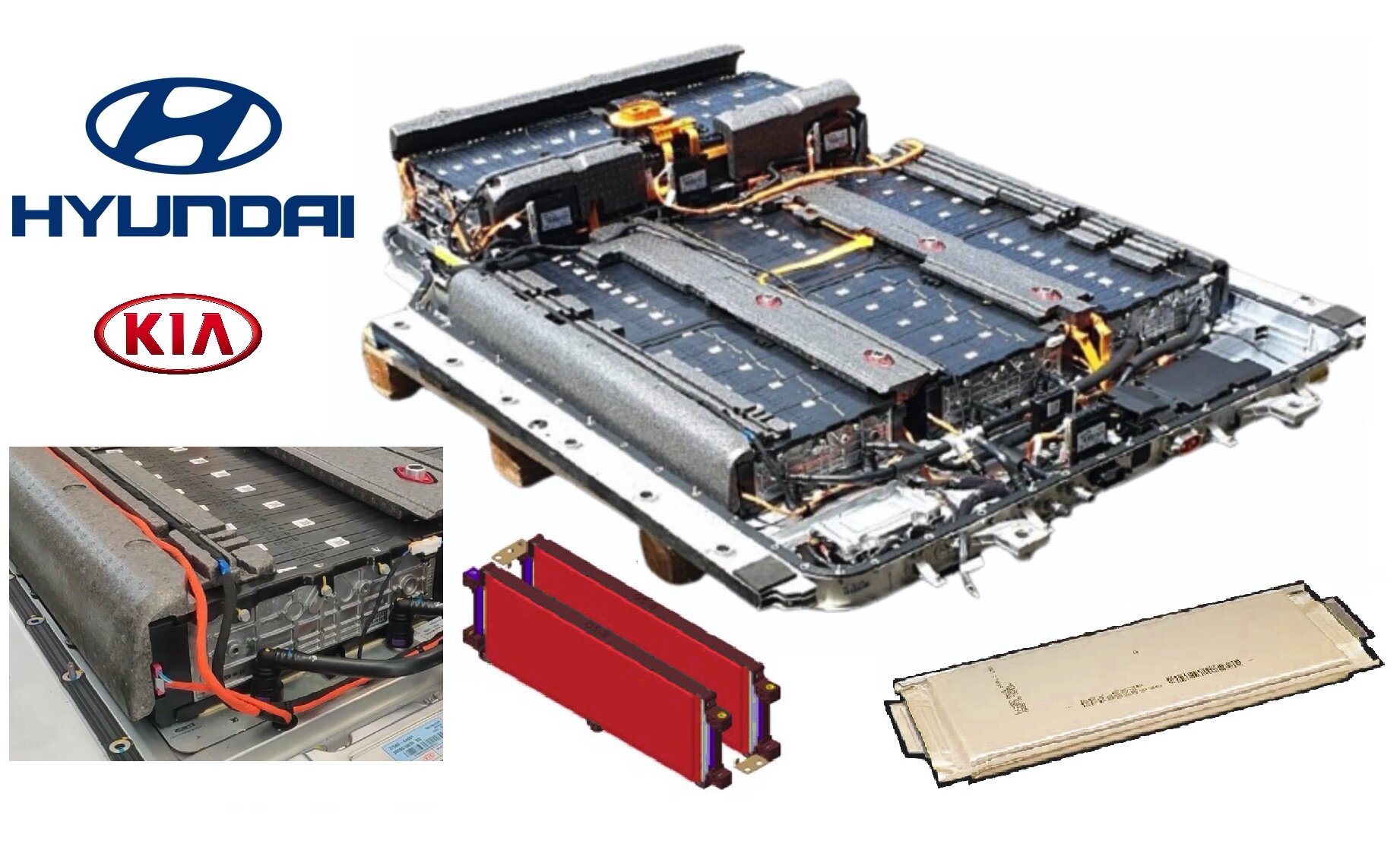

Hyundai KONA Battery Pack

In the Hyundai KONA Battery Pack, there is no proper rigid encasing around each module (contrary to the VW ID.3)? This sort of packaging is called “Cell-to-Pack” and presents lot of advantages (simplicity, light-weighting …) but also some challenges and risks (cell-alignment, thermal propagation and runaway, etc.)

The KONA Battery Pack is organised in 3p98s in which cells are wired together 3 by 3. Even if from the top the cells look like Prismatic, they are pouch cells (LG Chem) that are individually framed and vertically stacked

If you dismantled the modules ⚠️, you will find “runaway Arresting Device” (RAD) that are sort of electric controllers to switch off power if the cells are overcharged or at risk for runaway

Even if there are some Pads directly glued on the pouch cells, there is no proper Compression Pads because there is no module-boxing. Indeed, « true » Compression Pads have to be supported by something rigid because otherwise the compression is not uniform. The cell-to-pack battery structures are known to lack of compression and it is more difficult to properly align the cells. The compression is then not uniform and is only maintained following an « accordion » mechanism.

Compression Pads are very important when you use Pouch Cells because of swelling problem. Without Compression Pad, the pouch electrical connections are at risk ⚠️⚡️ and the cells can be deformed creating short-circuit ➡️ Fire risk

Hyundai recently (Feb 2021) recalled 76,000 KONA built between 2018 and 2020 following multiple Battery Fire 🔋🔥. This recall is said to cost $900 million USD to Hyundai which will be a large part of their revenue. This is their 2nd recall after modifying the BMS on some KONA but unfortunately without success to stop Fire risk.

You will notice the architecture of the Hyundai KONA is very similar to the GM BOLT 🤔: not only because they also use LG cells but also because both EVs are using Cell-to-Pack architecture. The GM BOLTs have also suffered from a recall for Battery Fire risk in Nov 2020.

If you want to understand Pouch Swelling issue and the importance of Compression Pads for Battery Pack Architecture🔋, you can refer to the OROVEL Card EV17. Runaway synopsis is described in OROVEL Card EV16