The RIMAC Nevera Battery

The RIMAC Nevera (previously named the C_Two) is one of the most advanced EV HyperCar produced by the Croatian team of Mate Rimac. RIMAC produces battery for the most prestigious BEV and Hybrids such as the Koenigsegg Regera, the Aston Valkyrie or the Pininfarina Battista.

The Nevera should be ready for 150 lucky customers from Q3 2021 and presents exceptional performances:

➡️ More than 1900 hp with of course all-wheel drive

➡️ 0 to 100 km/h in 1.97s; 0 to 300 km/h is 9.3s

➡️ Maximum speed = 412 km/h

Thanks to 4 Electric Motors (permanent Magnet)

Let's focus here on the Battery and what we can learn about it.

➡️ The battery is 120 kWh which is high capacity of course but let’s remind that some OEM like NIO already targets 150 kWh from 2022

➡️ Maximum voltage of the Battery = 730 V

➡️ Outstanding performance is from the power available from the Battery which can deliver 1.4 MW

➡️ Rimac claims 550km autonomy WLTP which is very good for such a high performance car

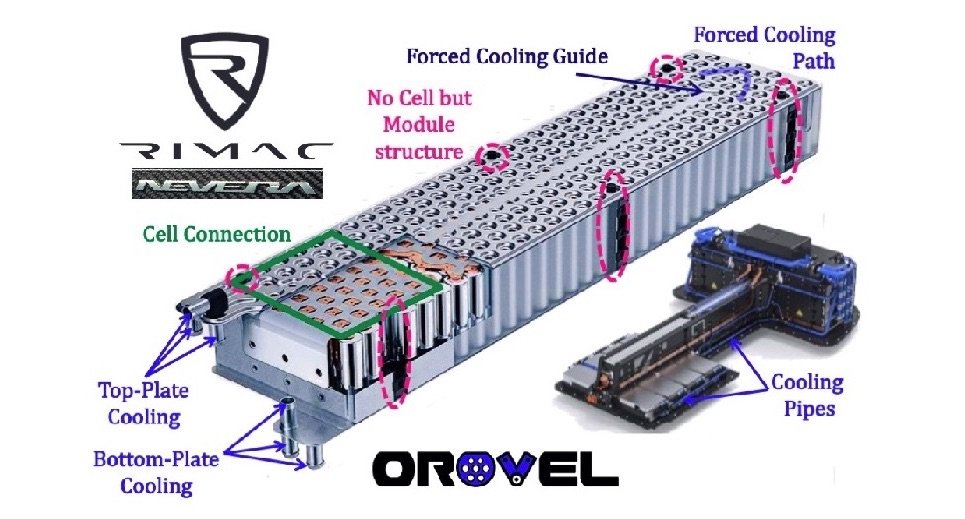

➡️ RIMAC is very well known for the development of Immersion cooling that they have used in several Battery packs such as the Koenigsegg Regera. But the Nevera uses instead a more-conventional Water-Glycol cooling. RIMAC said they did not chose the immersion cooling option for weight and packaging reasons. But the RIMAC cooling is still very special compared to conventional OEMs, Usually Water-Glycol systems run over dedicated channels or cooling plate under the battery pack. In the case of the Nevera, the cooling targets both the top and the bottom of the cylindrical cells and not the core of the cells (which means that the cell format must be elongate to fulfil this cooling strategy).

➡️ The pack contains 6960 x “21700 Cylindrical” cells. It is interesting to notice that the cell format is different from the Regera using 26700 Cylindrical cells. In the case of the Regera, as the cells are submerged by coolant, they can be thicker. In the Nevera the cell format is very elongated (so very different from the 4680 Tesla Cells)

➡️ RIMAC official specifications mention that the cell chemistry is Lithium Manganese Nickel. Please note that RIMAC never said it was NMC (Nickel Manganese Cobalt). LMNO (Lithium Manganese Nickel Oxide) is a slightly different chemistry (LiMn1.5Ni0.5O4) and has the advantage to offer very high voltage (5V) charging. Due to its high potential, LMNO has a higher energy density compared to lithium cobalt oxide and lithium iron phosphate so that LMNO can be used in high energy and high rate applications which is exactly the target of the Nevera RIMAC.

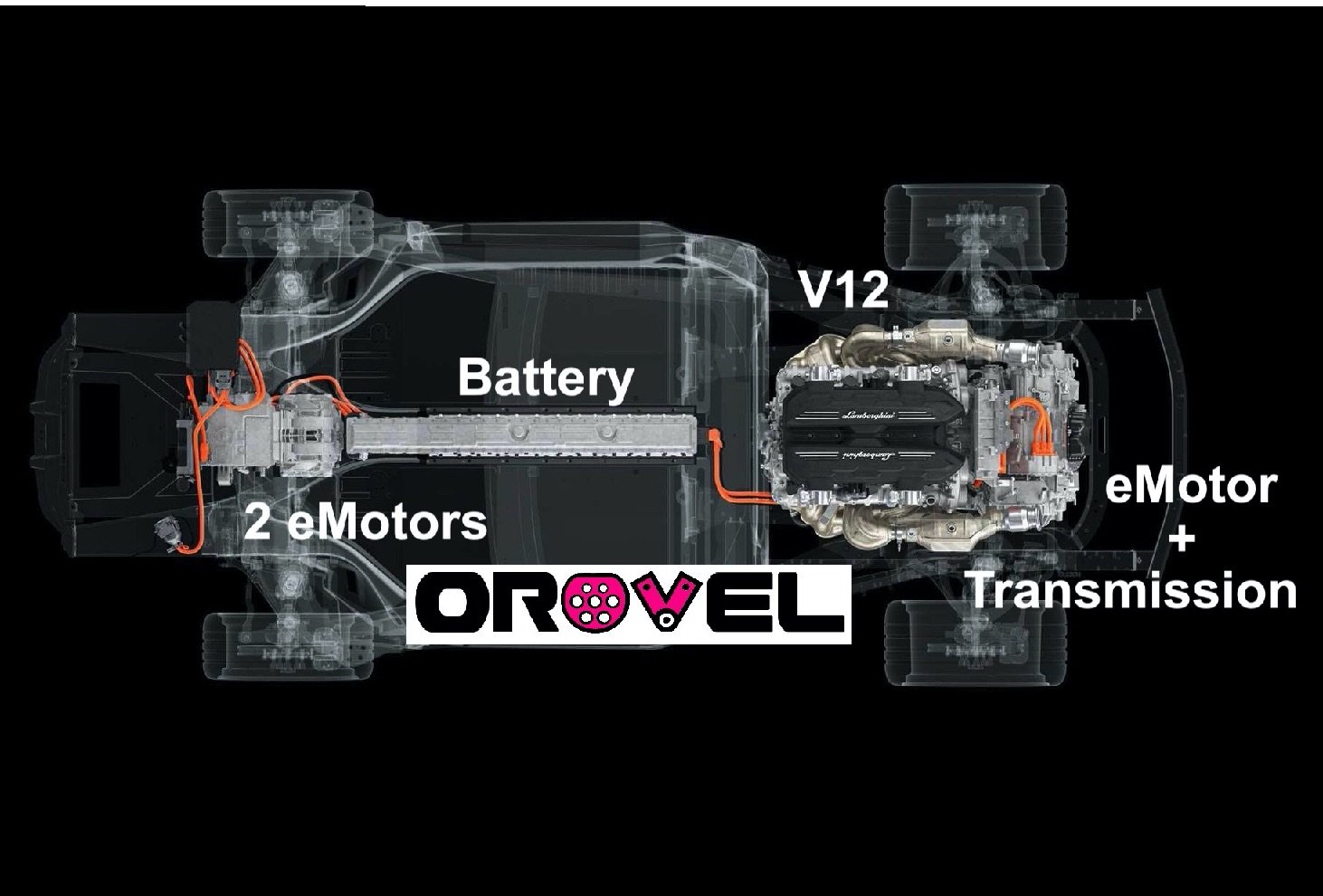

➡️ The Battery pack has a very particular form for a Full Electric Vehicle. This particular T-shape gives the Nevera several advantages: (1) the Battery is easier to maintain an optimise cooling flow (mass flow = 60L/min of coolant towards the Battery); (2) The Battery packaging is shaped to centre mass in the vehicle (similarly to any ICE HyperCar); (3) The Nevera can benefit from an integrated structural Battery.

➡️ The full analysis about the RIMAC Nevera Battery Module as well as its specific cooling is available here

References: official Technical Specifications